Ag and nursery industries are facing major labor shortages and a lack of qualified employees – the solution is to become more efficient with our processes and use automation to bridge the gap.

When automation is mentioned, people think complicated machinery and expensive equipment. This does not have to be the case. Just by picking the right container, you can make huge improvements without spending big. Here’s the 6 reasons to change to a Proptek®/Ellepot® container/insert system:

Save time on Seeding and Filling

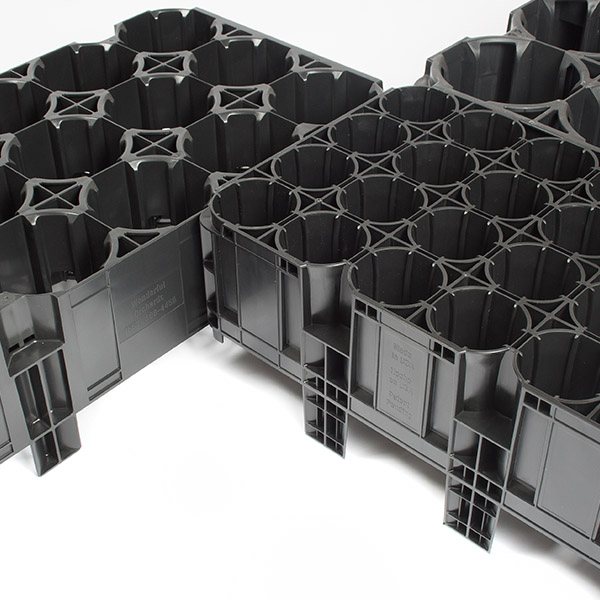

A tough injection molded container can be de-stacked automatically a lot easier than other types of tray. Using relatively simple bits of machinery and conveyors, the trays can be filled automatically, seeded and watered without a human hand ever touching them.

Save Time on Sorting & Grading

A system that allows you to remove each cell individually means that at all stages of growth, plants can be moved and inspected without pulling. When pulling to check the roots, the Ellepot slides very easily out without damaging the roots or plant. This saves a lot of time, but also saves money as fewer plants are lost.

Quicker Bumping up and Transplanting

Plants pull easier in a tough injection molded container that has been designed to create great roots. You can even get a “plant popper” that can pop out potentially hundreds of plants at once. This means less staff are required for the job or, looking it at from the other angle, keep the same number of staff but create the opportunity to grow and expand as a business.

Easier Moving Around the Nursery

Injection molded trays that remain rigid help here – especially if they include their own built-in feet. A large number of plants can be carried with an adapted forklift that has multiple prongs that can slide under the frames and take them to the greenhouse or shade house. This means you need fewer people – but also those people you do need are doing a much more enjoyable, safe and comfortable job.

Long-life Containers

Investing in a decent container is going to cost a few extra dollars. But the following year you won’t have to buy any. Nor the year after that. Nor the year after that… saving a lot of money in the long run. If the up-front cost is perhaps a little too much, you can often get finance to spread out the cost of injection molded containers over a few years.

Quicker Turnaround

Better roots mean better plants and that means happier customers. But better roots and better plants means quicker finishing and shipping out the door. This means more plants turned during a year, meaning more dollars per square foot of nursery – which means more money for you, the grower.