Details & Features

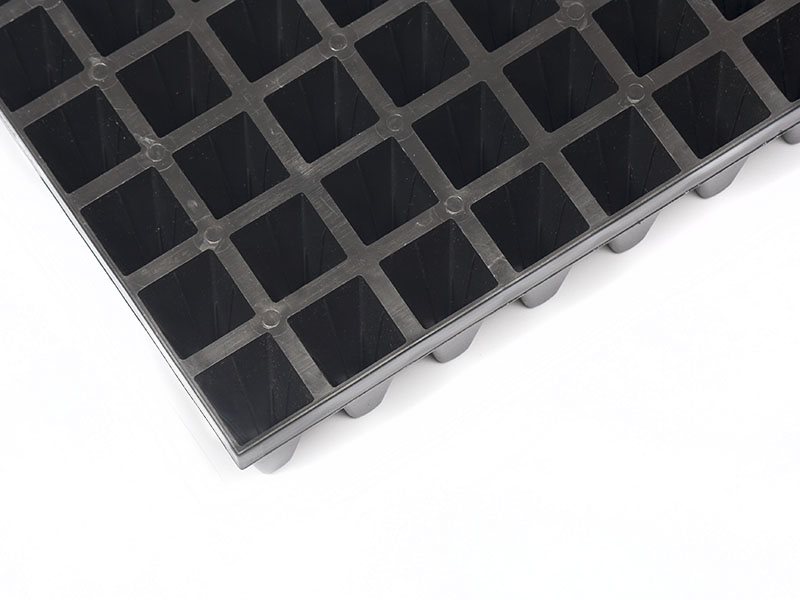

This shallower stacking 392 cell 26 x 13 inch tray with a 19cc cell volume is a good medium density processing tomato tray and is also well suited to celery, cabbage and cauliflower.

The injection molded construction lends itself to improved features over polystyrene (Styrofoam) trays, such as root training ribs and larger cell drainage hole. This means roots are better quality, circle less and can’t embed themselves into the cell wall – which all means a much easier plant to pull.

The heavy duty design has a long extended working life – usually 10+ years with multiple cycles per year.

Trays can be steam sterilized with no negative effects on life of tray or plant pulling.

Suitable for use with T-rail benching.

Key Features

Cell Count

392

Outer Dimensions

26" x 13"

Plant Density

159 pl/ft.2

Cell Volume

19 cc

Min Order Qty

252 trays

Made In

USA

Suitable For

Cabbage, Processing Tomatoes

Brussels Sprouts, Cauliflower, Celery, Lettuce, Peppers

Broccoli