Details & Features

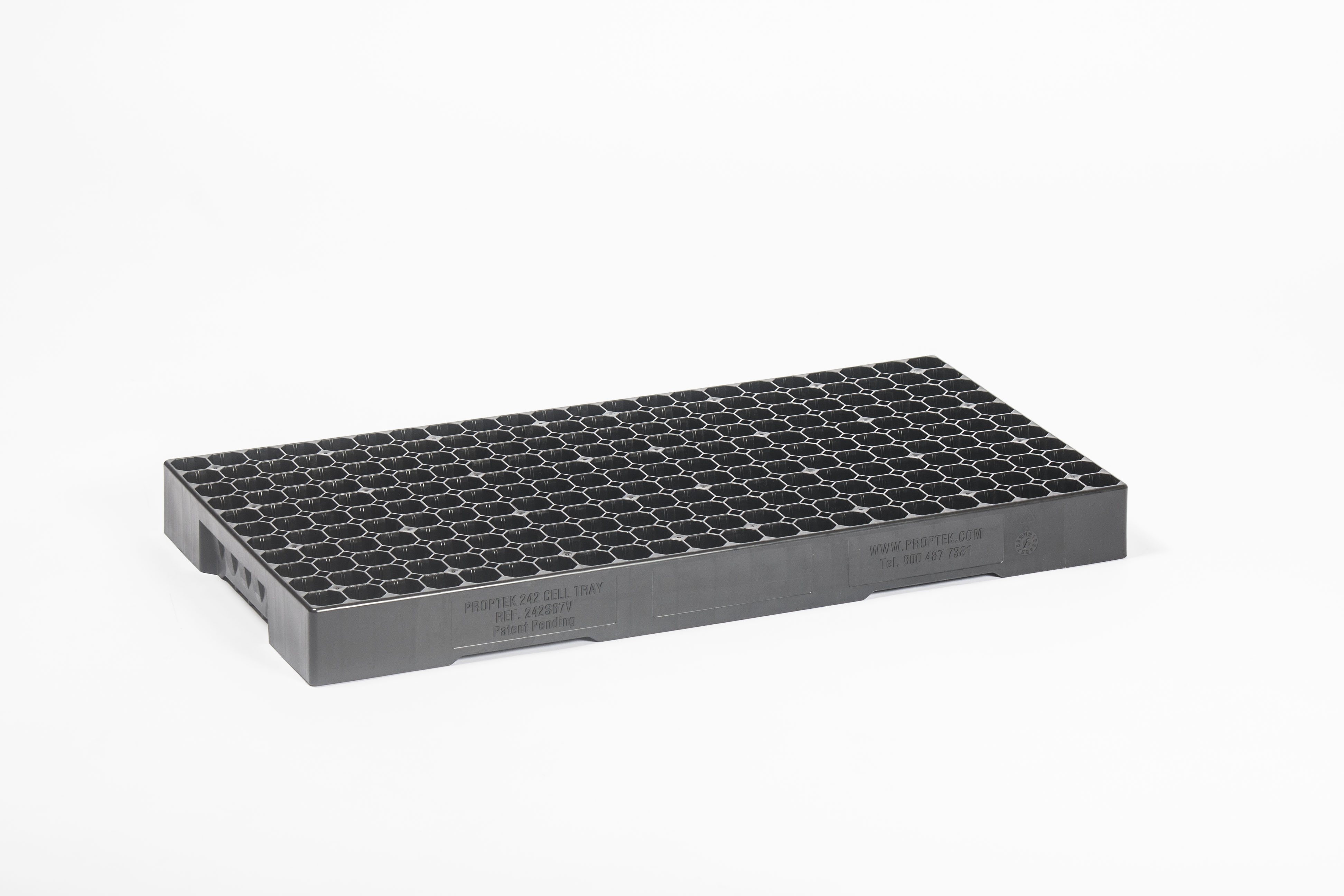

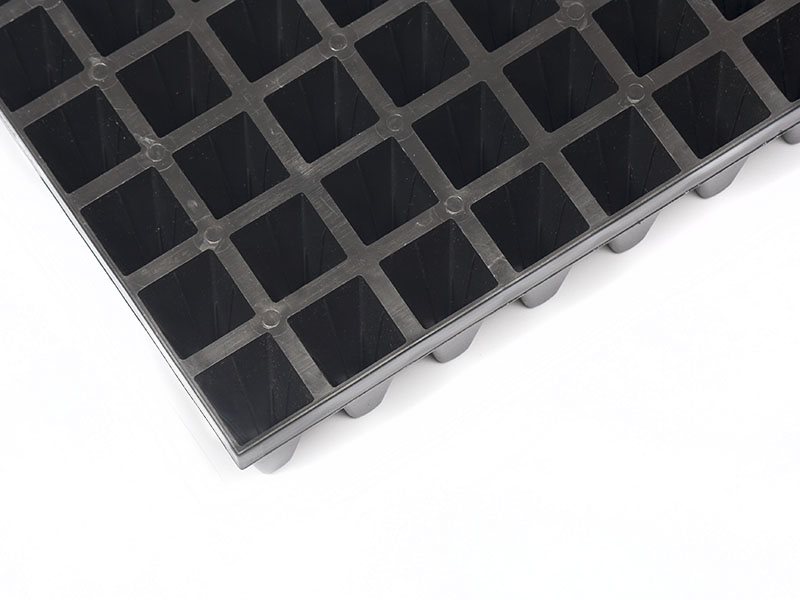

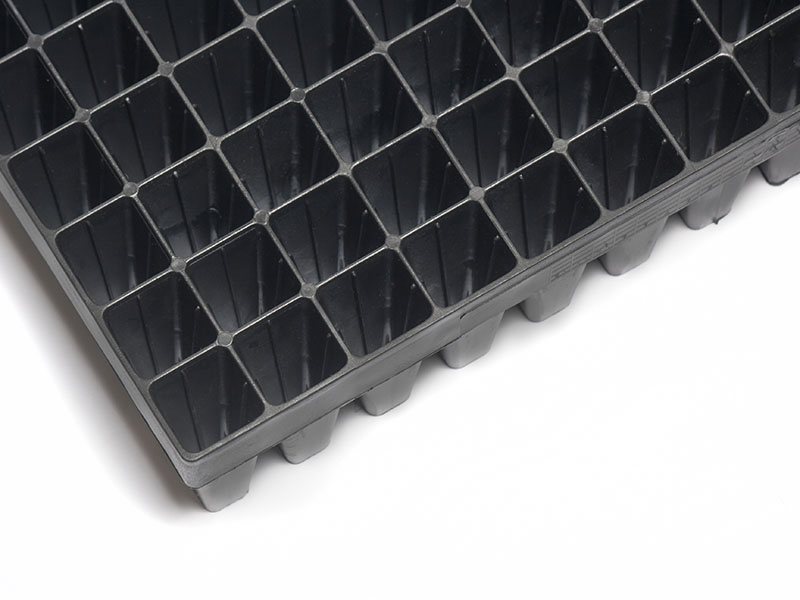

This 242 cell vegetable propagation tray has been developed specifically for the needs of growers in South Africa. It is designed to replace 200 and 242 cell Styrofoam trays. The cell volume is almost identical to the 200 cell Styrofoam tray but with 20% more cells, meaning more plants per square foot. Even though there are more cells in the same space as a 200 count tray, due to the strong nature of injection molded plastic the cell walls can be much thinner and there is no need for a thick outside rim. This means the plant spacing, i. e. centre to centre spacing, is very similar.

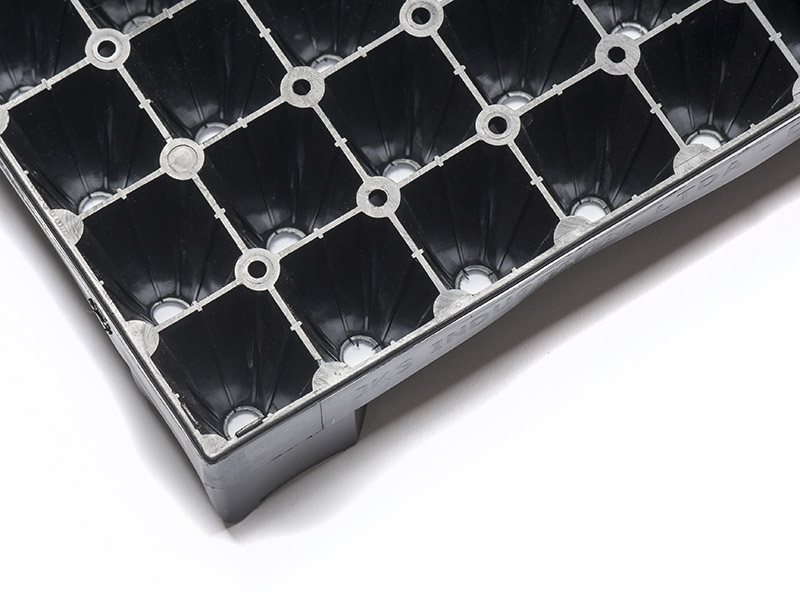

The Proptek 242 also features our patented root technology. Cells have internal vertical root training ribs to guide the roots down to the drain hole. This not only creates excellent roots that make the plant easy to pull, it creates a vertical chimney which aids aeration of the root ball and drainage. This all means a higher quality plant that is more likely to survive transplanting and grow vigorously.

Because of the injection molded construction and superior roots, plants pull very easily to help reduce any potential damage to the seedlings from transplanting.

The heavy duty design remains lightweight, but has a long extended working life – usually 10+ years with multiple cycles per year.

Trays can be steam sterilized with no negative effects on life of tray or plant pulling.

Key Features

Cell Count

242

Outer Dimensions

26" x 13"

Plant Density

98 pl/ft.2

Cell Volume

22 cc

Min Order Qty

216 trays

Made In

South Africa

Suitable For

Fresh Market Tomatoes, Peppers

Brussels Sprouts, Cauliflower, Celery, Melons

Cabbage, Lettuce, Processing Tomatoes